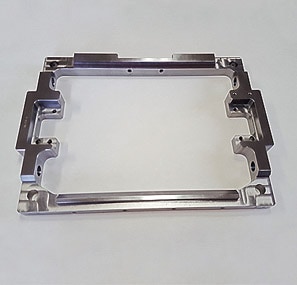

Pallet Frame for the Machine Tool Industry

As a machine shop that specializes in manufacturing close tolerance workpieces, we employ next-generation technologies to ensure an elevated level of quality and craftsmanship. Our exceptional performance has earned us many long-term partnerships and a loyal customer base.

Advanced Industries Inc. produced the pallet frame shown here for a company in the machine tool industry with whom we have a 25-year long history. It featured dimensions of 1.18” in length x 11.18” in width x 15.15” in height. We machined the part from a burnout blank of A36 stress-relieved hot rolled plate stock, which we then Blanchard ground, leaving just enough stock for surface grinding the thickness to size.

To machine the workpiece, we leveraged the benefits of our Mori Seiki NV5000 VMC. In addition to its precise positioning capabilities, this machine is equipped with a 1000 psi high-pressure coolant system. Using our own line of KoolBlast® tool holders, we directed a high-velocity stream of coolant directly at cutting zone, enabling us to achieve accelerated feed rates. We also facilitated setup for three machining passes by mounting the workpieces to a rotary indexing table. Post-machining, we gave the pallet frames a black oxide finish. Quality control involved first piece, in-process, and final inspection of all workpieces to confirm we achieved exacting tolerances of +.0007”/-.0000”.

The feedback we received from the customer was very complimentary. Notable mentions included the complete undercuts, square shoulders, and fine surface finishes. Our quality craftsmanship played an important role the ease of assembly and functionality of the final product.

For more detailed information about this project or our machining capabilities, contact us today.

PALLET FRAME SPECIFICATIONS

- Capabilities Applied / Processes

Gibbs Cam 3d Cam software, Blanchard Grinding, Surface Grinding, CNC Vertical Milling, Rotary Indexer

- Equipment Used to Manufacture Part

MORI SEIKI NV5000 VERTICAL CNC MACHINING CENTER W/ 1000 PSI HIGH PRESSURE COOLANT SYSTEM

- Overall Part Dimensions

1.18 X 11.18” X 15.15”

- Tightest Tolerances

.6299 DIA +.0007 -.0000

- Material Used

A-36 Stress Relieved Hot Roll Plate

- Material Finish

Black Oxide

- Industry for Use

Machine Tool

- In Process Testing / Inspection Performed

First Piece, In Process and Final Inspection.

- Volume

50 Pcs.

- Delivery / Turnaround Time

5 Weeks

- Standards Met

AS9100D and ISOAS9100D and ISO 9001:2015